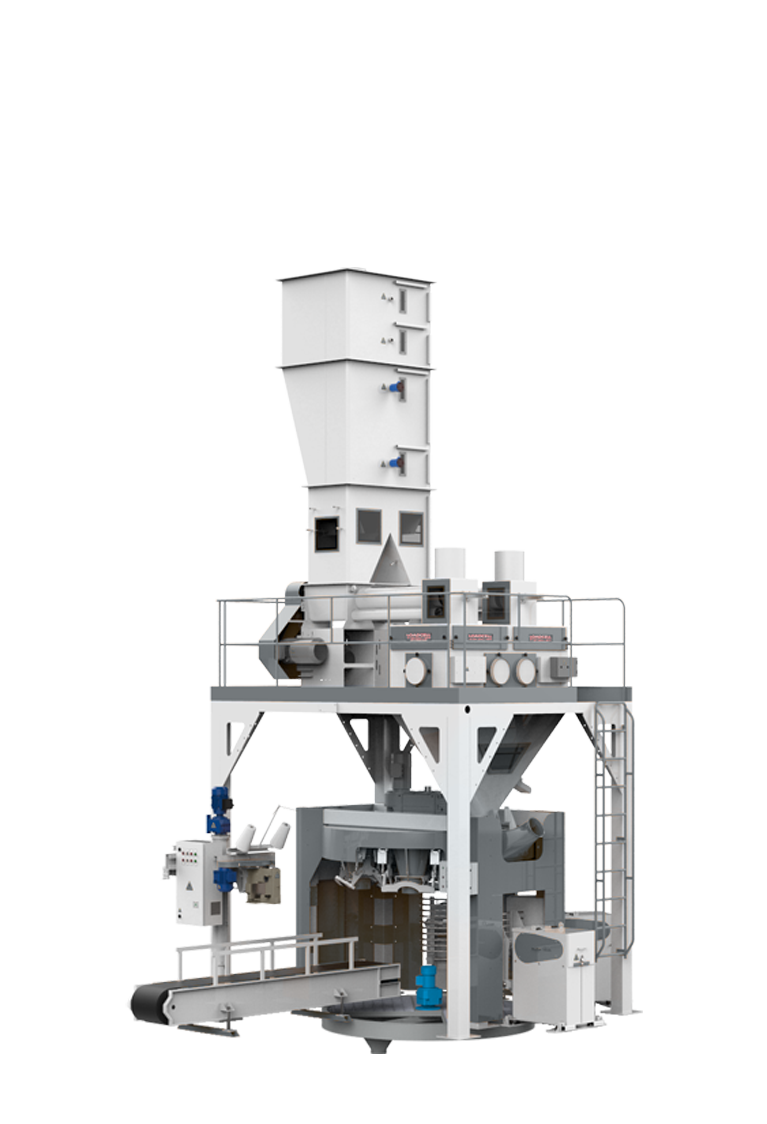

TREXIMAT

Roller Mill

The grain enters the roller mill through product inlet hopper, from which it is conveyed to the feeder rolls and then to the milling rolls.

QUANTUMINOX Stainless Square Plansifter

Through a new modular construction concept with the stainless steel, modules are connected to the central oscillating mechanism.

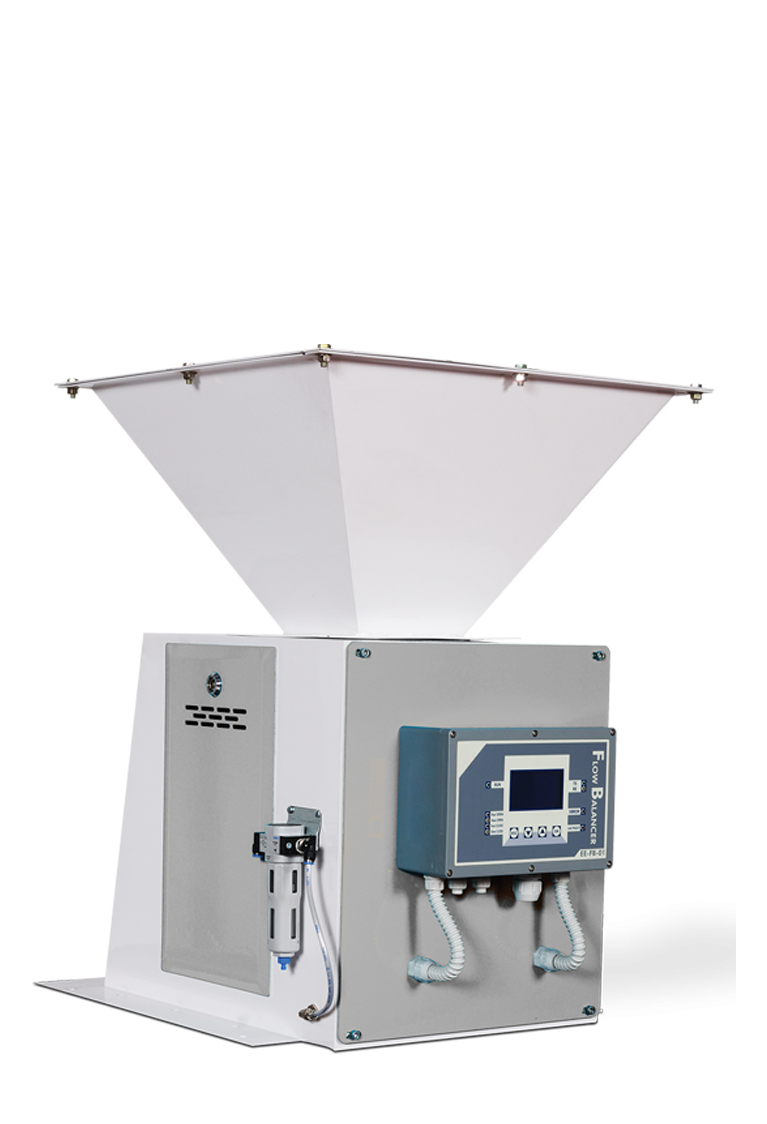

Purilina Semolina Purifier

The Purifier is used for the cleaning and classification of semolina, in wheat/maize flour and semolina mills. The product flow rate is adjustable by regulating plate then product can be spread uniformly on the surface of screen.

FOURCLEAN Combinator Model F1 & F2

Heavy and light wheat classification is made on the first screen. At the same time the parts are separated according to their weights.

Flour Milling Equipment

Pioneers in Flour Milling and Feed Equipment Manufacturing

A leading Turkish company in the field of flour milling and feed equipment manufacturing., a leading Turkish company in the field of flour milling and feed equipment manufacturing. The company has established itself as a major player in international markets through its innovation strategy and quality focus. With over 20 years of experience,

Modern Technology

Experience Engineers

discover Our products

We are driven to improve the lives of our clients, our employees, and our community through our commitment to leadership, excellence in craft, and attention to detail.

discover Our technology !

Gmach new Treximat

Roller Mill

Designed with new generation technology, Treximat Vals is a flawless work presented to the milling industry by experienced engineers and industrial designers

Through a new modular construction concept with the stainless steel, modules are connected to the central oscillating mechanism.

Due to technology applied in construction of the compartments, stainless material and the new concept, Quantuminox enables to increase number of compartments without having to go through any significant changes in the project

It is used for the sifting and classifying of grinded grain that comes from one or two inlets.

The machine is divided into three sections:

A central body with counterweight rotated shaft and two lateral cabins housing the sifting channels.

All welded points are welded by robotic welding system in order to prevents human caused fault.

Upper pressure mechanism is placed at the outside to obtain easy maintenance and usage is simplified.